Taian Haishu Machinery Co.,Ltd.

Telephone: +86-538-8606169

Fax: +86-538-8606169

Address: Zhouwangzhuang Village, Shankou Town

Taian City Shandong Province China

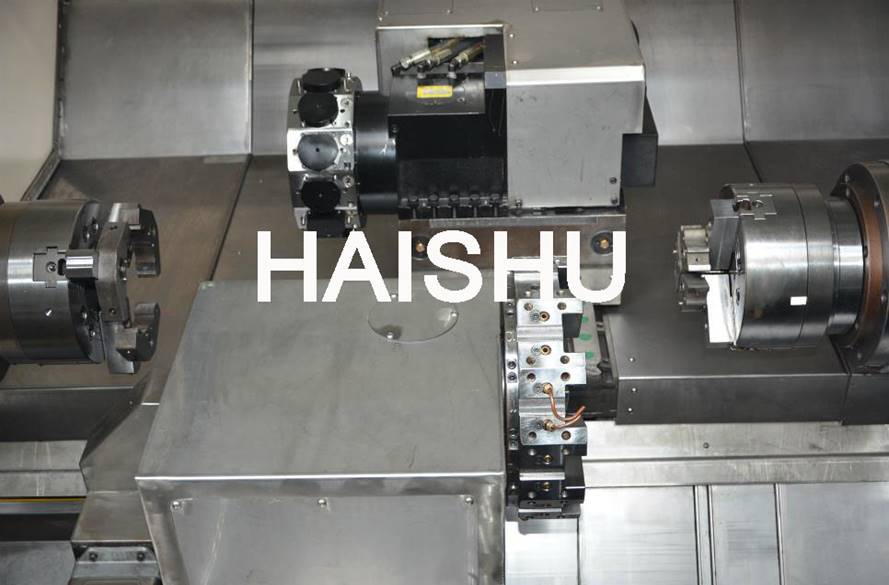

CNC350T two spindle two turret CNC turning center

| ,

No. |

Item |

Unit |

specifications |

|

CNC350T | |||

|

1 |

Max.rotation diameter on lathe’ body |

mm |

350 |

|

2 |

Max.workpiece lengt |

mm |

750/1000/1500 |

|

3 |

Max.turning diameter |

mm |

300 |

|

4 |

Spindle nose type and code |

mm |

A8 |

|

5 |

2-Hydraulic chuck |

mm |

2-φ200 (8") |

|

6 |

Front spindle bore taper |

1:20 | |

|

7 |

Spindle bore |

mm |

50 |

|

8 |

2- Servo spindle speed range |

mm/min |

0-4000 |

|

9 |

X/Z/B Rapid traverse |

mm/min |

40000 |

|

10 |

Cs1,Cs2 main servo motor power |

kW |

7.5 |

|

11 |

C-axis(Turret power axis) motor power |

kw |

3.7 |

|

12 |

X/Z-axis motor max.torque |

N.m |

10 |

|

13 |

Y-axis travel(optional) |

mm |

+35/-35 |

|

14 |

B-axis(sub-spindle) motor max.torque |

N.m |

15 |

|

15 |

Power specifications |

v |

380±10%. 50Hz±1Hz |

|

16 |

Turret transfer time (one station) |

s |

1.6(Horizontal12) |

|

17 |

Turret transfer repeat positioning accuracy |

mm |

0.005" |

|

18 |

X1/X2-axis travel |

mm |

200 |

|

19 |

Z1/Z2-axis travel |

mm |

1100/1350/1850 |

|

20 |

B-axis (sub-spindle) travel |

mm |

1400/1650/2150 |

|

21 |

2-C axis(Turret power axis) max.speed |

rpm |

4000 |

|

22 |

Biaxial dynamic docking concentricity |

mm |

0.005 |

|

23 |

Ydraulic servo turret form |

2-Horizontal 12-station power turret | |

|

24 |

Turret cylinder clamping force |

kg |

4240 |

|

25 |

Turret hydraulic power source |

kg/cm² |

40 |

|

26 |

Power tool holder specification |

VDI40 DIN5480 | |

|

27 |

Knife handle size |

mm |

□20×20 |

|

28 |

Net weight |

kg |

5500 |

|

29 |

Size(L×W×H) |

mm |

2700/3000/3500×1650×1900 |

Standard configuration:

◆CNC system: GSK

◆Two servo spindle unit

◆Two hydraulic center solid chuck

◆Horizontal 12-station power turret

◆5-Axis line rail

◆Turning cooling system

◆Automatic lubrication system

◆The whole protection system

Select Configuration:

◆CNC system: SYNTEC, Fanuc, Siemens

◆Increasing the Y-axis

◆Two hydraulic hollow chuck

◆Automatic feeder

◆Automatic chip conveyor

◆Automatic pick pieces equipment

◆Automatic protective door

◆Loading and unloading robots

CNC lathe research and development, every problem we can not be ignored!

How to make my machine have a longer service life?

How to make the equipment have higher production efficiency?

How to ensure that the machine is simple to learn?

... ...

Learn CNC lathes

From the beginning our website!

Global Service Hotline:+86-0538-8606169